drill press restoration

My wife remembers this drill press gathering dust in her grandfather's little home shop. It didn't get much use because larger drill presses became available and for most woodworking, this is too small.

But for the scale of my watchmaking, a drill press this size is just the thing. It hadn't seen oil since the 50's so it was a little crusty. And that teetering pile it was connected to wasn't appropriate for the tiny work I do.

So, first, took it apart, some penetrating oil and brushing. Wire brushed the frame and a new coat of paint:

My late father-in-law (from whom I got this drill) would have loved the bright red, it was his favorite color!

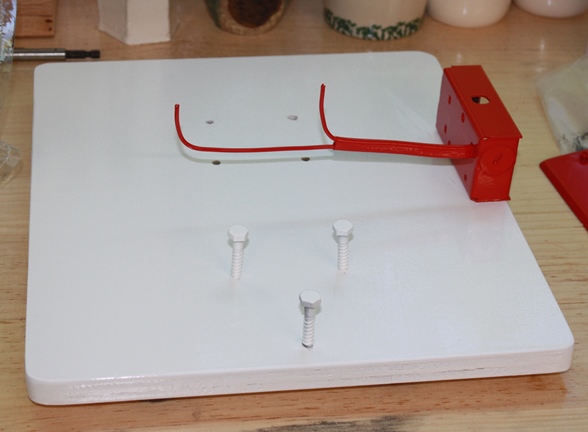

I mounted it just like my other tabletop machines (a lathe and mill) on a white painted plywood base with large grippy feet. When I got it, the way the motor was turned on was by plugging it in--with an old cloth wrapped cord. I installed a new wiring harness:

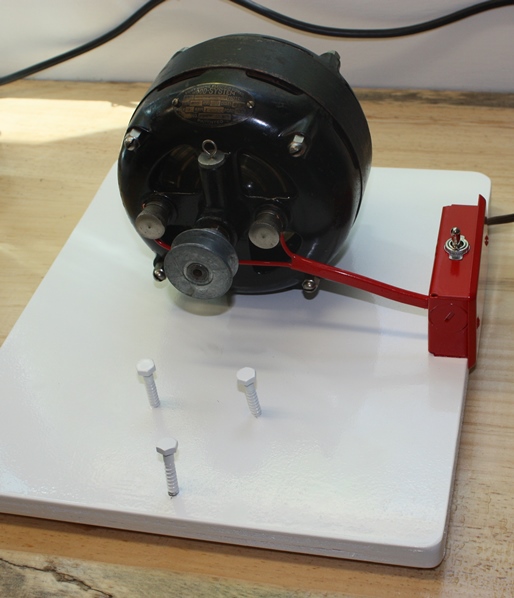

I rebuilt the old 1/8 HP induction motor, had to remake one of the missing oil caps, and I created a new pulley as well. Here is the cleaned-up motor attached to the platform (with bolts from below) and a new old-fashioned switch:

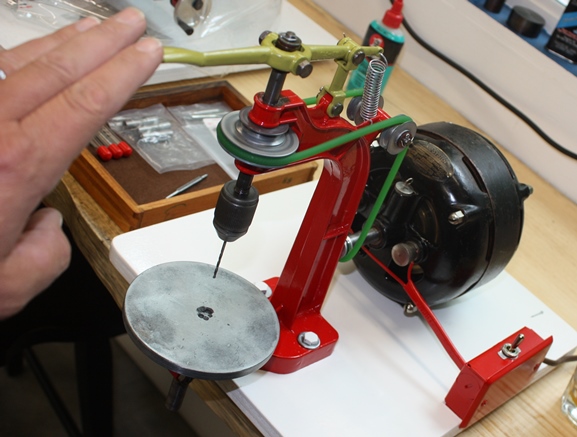

I got some fusible belting and made a polyuratane belt (perfectly tight when on the larger spindle pulley). No color choice but I thought it made a nice accent to the red frame. Here's the rebuilt drill press:

Ready to drill:

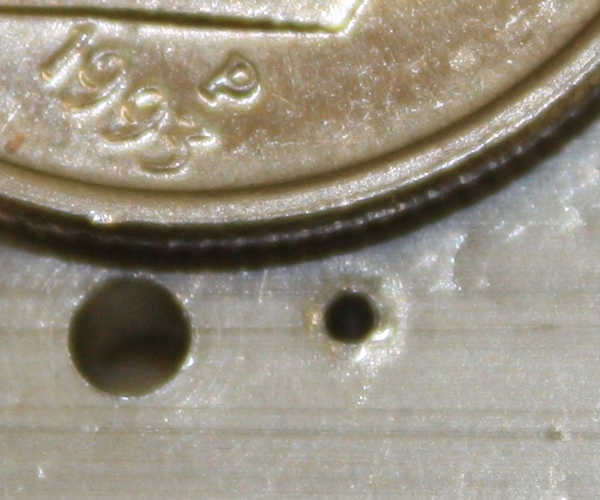

A 'big' hole (1.5 mm) and a 'small' hole (0.5 mm) done with the new press:

My wife made a vinyl cover for it to match the ones she made for my lathe and mill: